Overseas projects

Our mission

We provide support with a view to transferring technology to the local market, particularly in Southeast Asia, where economic development continues to grow.

We are involved in the construction of a variety of infrastructure overseas in our role as specialists in tunnel design and construction.

Urban infrastructure such as subways is currently being constructed in urban areas with remarkable economic development in Southeast Asia, such as Vietnam and the Philippines. The construction of infrastructure using various tunneling methods is also underway in regions such as Panama and Nepal under ODA from the Japanese government. We participate in such overseas infrastructure projects as tunnel specialists, providing technical support from surveying and design during the planning stage, to construction management and post-construction maintenance.

Japanese seismic tunnel design technology is in demand.

Because Japan is an earthquake-prone country, its seismic tunnel design technology is among the best in the world. The accumulation of knowledge that has resulted in safe and long-lasting tunnels in earthquake-prone areas is unparalleled. The know-how we have gained from the aftermath of natural disasters is now in demand for the construction of infrastructure in other countries suffering from natural disasters, and as specialists in tunnel design, we have been involved in the construction of a variety of infrastructure overseas.

Transferring technology to local engineers to enable them to maintain and upgrade infrastructure.

Our goal is to transfer the technologies necessary for surveying, design, construction, and maintenance to local engineers for the construction of tunnels and other civil engineering infrastructure, and to ensure that local infrastructure can be managed over the long term. To achieve our goal, our engineers are active in various countries and regions around the world.

Business overview

On-site surveying of foundations and groundwater, etc.

First, a survey of the foundations, groundwater, and the presence of other underground structures is conducted at the proposed construction site. For example, in the case of subways, surveys are conducted to determine what lays under the ground between each station based on urban planning.

Tunnel design

Based on the survey results, the construction method is selected and drawings for the tunnel design are prepared, taking into account the foundations and groundwater conditions along the route, and the presence of underground and aboveground structures. In doing so, we also give due consideration to disaster prevention and maintenance management when the tunnel is in service.

Construction management

We provide assistance in tunnel construction projects to ensure the project stays on schedule in our role as construction supervisor. Based on the information they collect, engineers personally check whether the construction is progressing properly according to the construction method and construction period specified in the design drawings. We also provide the best advice and resolve any unexpected problems that may arise during the construction phase at the earliest possible time.

Maintenance management

Our focus in this area is the transfer of the skills and experience needed to maintain tunnels over the long term. The goal is to teach what kind of periodic inspections and repair work is necessary for the safe management of infrastructure and when, and ultimately to enable local engineers to perform maintenance, management, and renewal independently.

Our strengths

Extensive experience in overseas projects.

Starting with our participation in the renovation of the Ahmed Hamdi Tunnel in Egypt (a road tunnel under the Suez Canal) in 1992, we have been instrumental in many overseas projects. Our key strength lies in the knowledge we have accumulated over nearly 30 years in the industry.

Projects

Renovation of Ahmed Hamdi Tunnel

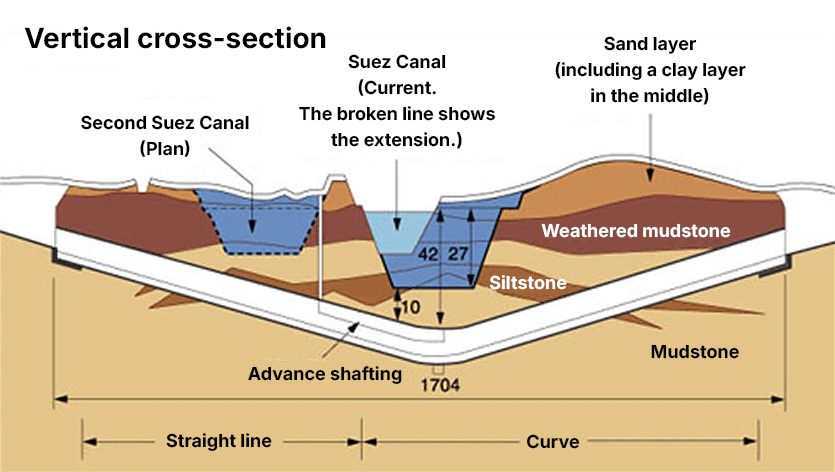

The Ahmed Hamdi Tunnel is a road tunnel that crosses under the Suez Canal. It was originally constructed by the British government in 1983 as a shield tunnel. Its total length is 1.63 km and its outer diameter is 11.6 m. Shortly after completion, it was discovered that seawater was leaking from the reinforced concrete lining. The seawater quickly corroded the rebar and caused the concrete to deteriorate, resulting in serious deterioration of the tunnel lining.

In 1992, a tunnel rehabilitation project was initiated with grant aid from the Japanese government. We established a joint venture with Nippon Koei and participated in this project at the request of the Japanese government. Our work included surveying the deteriorated condition of the tunnel lining, determining the appropriate retrofit method, design, on-site construction supervision, and implementation of a monitoring and maintenance system.

Final Joint Improvement Plan and Construction Drawing Review for the Hong Kong-Zhuhai-Macau Bridge and Artificial Island Tunnel Project

We provided assistance to the Chinese contractor on submerged tunnel design, construction technology, and construction supervision technology for the world’s longest submerged tunnel, the 6.7 km reinforced concrete structure of the Hong Kong-Zhuhai-Macau Bridge, which was opened to traffic on October 23, 2018. We also assisted in the development of the world’s first extrusion-type watertight final joint construction method.

Nepal|Nagdhunga Tunnel Construction Project

In Nepal, a country where the development of efficient road networks is lagging behind, we are participating in a project to construct a tunnel on the Nagdhunga Pass, located on the main road connecting the capital city of Kathmandu and other major cities.

The project facilitates the transportation network along this section of the route, responding to rapidly increasing traffic demand, shortening travel time, and improving traffic safety, thereby contributing to the promotion of social and economic development in the region.

Other business fields

Contact

Inquire here for information on our services and recruitment information, etc.